Extrusion, modification, blending: The technologies for refining our wheat-based products.

Being a specialist for wheat also means that we know how it has to be provided in order to develop application-oriented solutions. In addition to knowledge, passion and experience, it is the technological knowledge that makes the difference at Crespel & Deiters. Once the grain has been ground into wheat flour, we break it down into its components. By sifting and centrifuging, we then obtain our wheat-based products of wheat starch, wheat proteins, wheat fibres, and wheat extracts. With innovative refining technologies, we create highly-functional products for food, animal feed and technical applications.

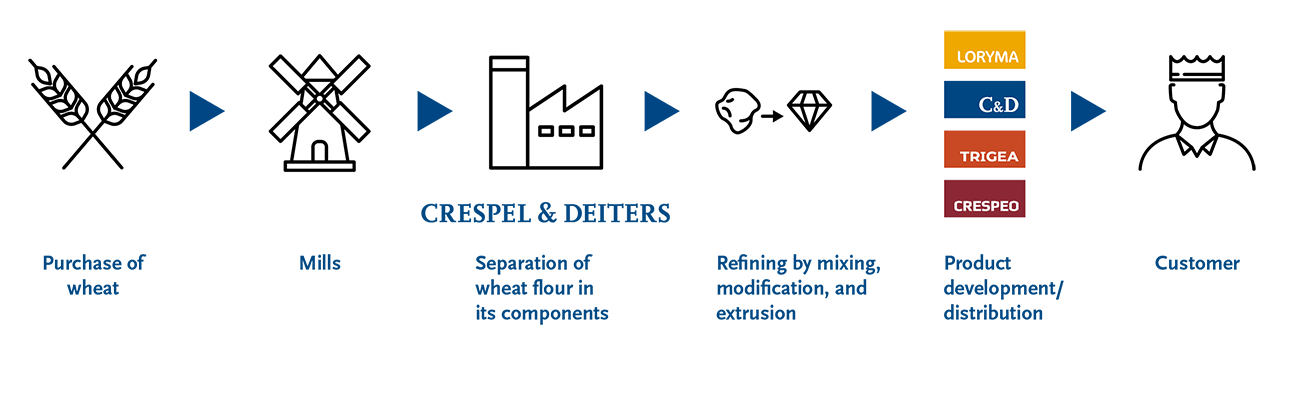

More than a wheat starch factory: The refining technologies within the Crespel & Deiters value chain.

From purchasing to cutting and refining the wheat, right up to the customised product for our customers, everything comes from a single source at Crespel & Deiters. This is because the Crespel & Deiters Group controls the Group’s entire, increasingly sophisticated value chain. With all the necessary competences and technologies under one roof. With ever new and more complex products for international customers who have a huge array of wishes and requirements. The wheat-based raw materials are produced at Crespel & Deiters. The extrusion is performed at the Extruded Cereal Products B. V. specialist, a 100% subsidiary of the Crespel & Deiters Group. Modification and blend will be taken over by the experts in Ibbenbüren and Zwingenberg. The resulting highly-functional products are distributed by the brands of Crespel & Deiters Group.

Refining technology Extrusion

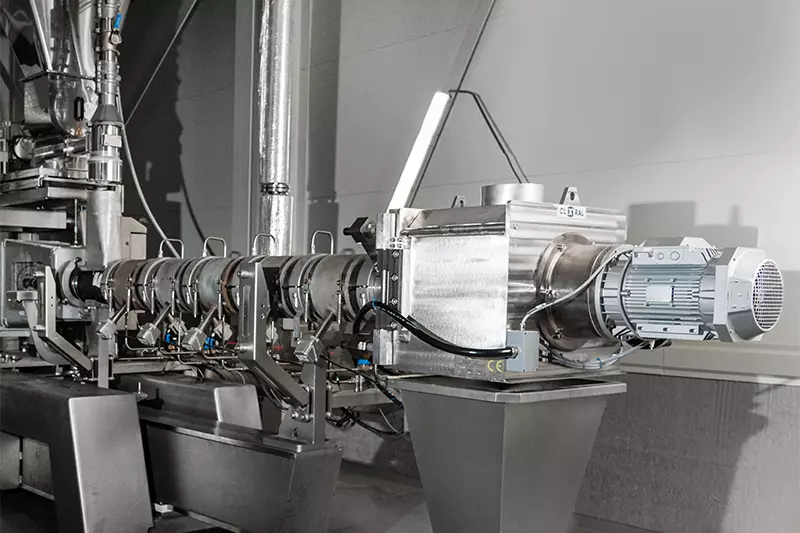

At Crespel & Deiters, extrusion is the innovative refining technology for wheat, cereals and proteins, where new and innovative products can be obtained through a complex thermo-mechanical process. Shape, flavour, nutritional composition, and other properties can be created by means of extrusion.

Refining technology modification

In the Crespel & Deiters Group, wheat starch is modified using refining technology to pave the way for innovative, customised products in the food and petfood industry as well as in the manufacturing of paper & corrugated board, for instance, which are precisely adapted to the customers’ specific requirements.

Refining technology blend

At the Ibbenbüren and Zwingenberg sites, functional wheat-based blends are created from wheat-based products, by making use of blending refinement technology. Binding systems, texture systems, stabilising systems, breadings, and coatings as well as brine additives for the food industry are produced here at the Zwingenberg site according to special recipes. Ready-to-use solutions for the production of gravies, jellies and sauces are also mixed for the pet food industry. In Ibbenbüren, more than 150,000 tonnes of binders are blended annually for technical applications.

Refining technology extrusion: Wheat, grain and protein extrudates for innovative product developments.

Texturates and pregelatinised wheat flours from refining technology extrusion

Our technology extrusion for the refinement of wheat, cereals and proteins opens up a multitude of design possibilities for end-consumer products. Especially in the food industry, the resulting texturates, such as textured wheat proteins, can be used to drive the development of vegetarian and vegan products, protein-rich snacks and sports nutrition.

Extruded pregelatinised flours are used in the production of baked goods, confectionery and convenience food. Both textured wheat proteins and pregelatinised flours are used to naturally optimise pet food Pre-gelatinized flours are also a natural nutrient substitute in milk replacers. With their specific properties, pre-gelatinised flours are suitable for various industrial applications such as pelleting, coating, gluing and binding.

Refining technology modification: Modified wheat starches for an improved product performance.

Modified wheat starches from refining technology modification

With our refining technology modification, we make wheat starch more stable for a number of manufacturing processes such as, for instance, heating. Thus, our customers’ end-consumer product is more process-, heat-, acid- and shear-stable as well as more emulsifiable. In the food and petfood industry, the hot-swelling and cold-swelling modified wheat starches are used as binders in pasteurisation, ultra-high temperature or hot and cold production of sauces and fillings. In the technical sector, modified wheat starch ensures optimal binding. Our wheat starches are used in our wheat-based, high-performance adhesives for corrugated board manufacturing and also for optimising various bonding and binding processes for technical applications such as pelletising, briquetting and granulating.

Refining technology blend: Wheat-based solutions close to the customers.

Functional wheat-based blends per refining technology

With our functional wheat-based blends, we provide the food industry and the petfood industry with solutions that enable them to optimise their products efficiently. In petfood, we improve the feed’s sensory properties, appearance, texture, and stability. In the food industry, meat, veggie and convenience products are optimised in terms of binding, texture, stability, shelf-life, gel-security, consistency and taste. In addition to technology and know-how, our high level of expertise in combining wheat-based raw materials and products guarantees an effective, application-specific, high-quality blend.