Hydrolysed wheat protein: functional ingredients and plant-based source of protein

As a vegetable protein source, hydrolysed wheat protein not only improves the nutritional profile of sports nutrition – Lory® Protein H11 and H12 can also increase the protein content in product groups outside the sports nutrition segment. ‘High Protein’ is a growing trend. For instance: protein-rich baked goods as well as nutritionally-optimised plantbased alternatives are in high demand among healthconscious consumers.

Soluble wheat protein optimises both the physiological nutritional profile, as well as other product characteristics such as texture and processing. The functional properties result from the gentle enzymatic hydrolysis of vital wheat

protein. The protein powder is easy to dose and forms a homogeneous dispersion in water, making it ideal for application in a wide range of foods.

Optimise the nutritional content of your products with Lory® Protein hydrolysed wheat proteins!

Water-soluble wheat protein optimises both the physiological nutritional profile, as well as other product characteristics such as texture and processing. The functional properties result from the gentle enzymatic hydrolysis of vital wheat protein. The protein powder is easy to dose and forms a homogeneous dispersion in water, making it ideal for application as a plant-based source of protein in a wide range of foods.

- Broken down vegetable protein

- Neutral taste, no off-flavour

- Contains valuable amino acids like glutamine

- Easy handling and simple dosing

- Forms a homogeneous dispersion with low viscosity in water

- Low foam formation

- Heat- and pH-stable

- Good digestibility

- Nutritional profile can be enhanced by combining with other protein sources

- Optimised baked goods, e.g. bread, pastries and patisseries

like biscuits, shortbread, muffins etc. - Protein and muesli bars

- Protein shakes

- Injection brines for meat applications

- Glazing agent as an alternative to eggs and milk

- Unobtrusive, slightly acidic taste

- Light colour

- High protein content (min. 82,3% (x6,25; TS))

- Functionality (average emulsion capacity, foaming behaviour, gel formation, solubility)

- Good dispersing properties

- Good sensory properties

- Good digestibility

Protein enrichment of plant-based alternatives (e.g. boiled sausage, fish, bacon, pasta) and hybrid products

Solubility in water: the difference between vital and hydrolysed wheat protein

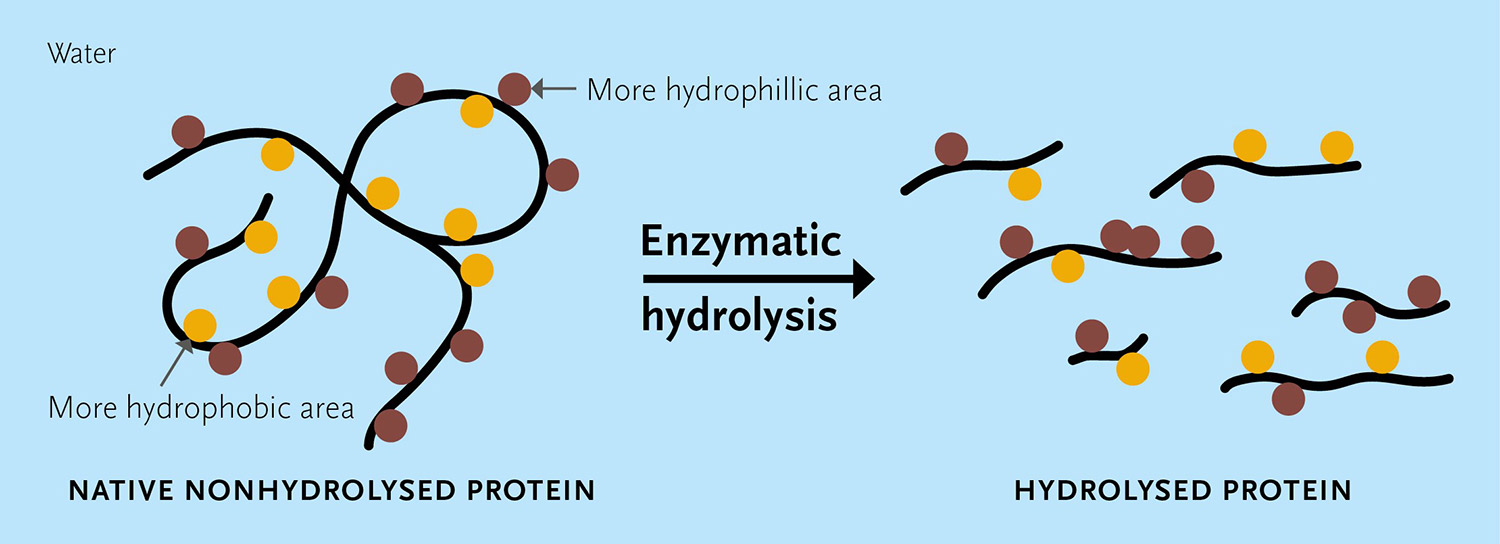

Vital wheat protein (gluten) primarily comprises protein fractions of glutenin and gliadin, which form a dough on contact with water or with mechanical action (kneading). This directs the hydrophobic areas inwards and the hydrophilic areas outwards. Due to the formation of such water-repellent agglomerates, which give doughs a viscoelastic structure, gluten is also called gluten.

Enzymatic hydrolysis shortens the molecular chains, preventing agglomerates from forming. The polar amino acid residues of the hydrolysed wheat protein can be well hydrated, which opens up other areas of application than for gluten.

| Vital gluten | Lory® Protein H11 | Lory® Protein H12 | |

|---|---|---|---|

| pH stability | pH reduction changed at high pH values | pH stable | Denatures the properties |

| Heat stability | Denatured when exposed to heat | Heat-stable | Denatured when exposed to heat |

| Gelation | Forms strong gels | No gelation | Weak gelation |

| Emulsion | Medium emulsion activity, but difficult to disperse | Weak emulsion activity | Medium emulsion activity |

| Foam formation | Medium foam formation, but difficult to disperse | Weak foam formation | Medium foam formation |

Plant-based Mortadella (boiled sausage)

Thanks to the Lory® Bind wheat-based binding component, the vegan sausage patty has an elastic and firm texture. And, thanks to its enrichment with hydrolysed wheat protein (Lory® Protein H12), it has a similar protein content to classic meat cold cuts. Optional additions such as bell peppers or mushrooms can be used. The mouthfeel is very similar to that of the animal-based original, yet the sausage alternative has significantly less fat, is low in sugar and contains additional fibre.

- Protein content up to 12 % (comparable with the classic

Mortadella sausage) - Authentic mouthfeel with a firm, non-rubbery bite

- The plant-based alternative’s colour shades are

adjustable, as Lory Protein H12 is a light-coloured protein - Good emulsion forming properties and at the same time well soluble

- Production analogous to the classic cutter process

Baked goods

Depending on the application, the hydrolysed wheat protein can be used primarily as an additional source of plant-based protein or to optimise doughs.

Possible applications for the protein enrichment of baked goods

Lory® Protein, as a plant-based source of protein, is ideally suited for the production of nutritionally optimised high-protein/low-carb baked goods such as muffins, biscuits, sponge cakes, wafers or crackers. The ingredient interacts only minimally with the dough, so the other product properties such as texture are not affected.

You can find more information in our press release High Protein Muffin

- Increased protein content with the same texture

- Functional added value: in baked goods containing wheat flour, with no additional allergens/e-numbers declaration

- Easy processing

Possible applications for improving dough properties

Particularly in yeast-raised or drawn doughs such as biscuits, flaky and puff pastry as well as pizza doughs, Lory® Protein H11 can be used as a functional ingredient that has a positive effect on the dough properties. The wheat proteins interact with the gluten in wheat doughs and relax the dough. In many cases, this can improve machinability and thus increase production efficiency.

- Reduced elasticity (less ‘snapping back’ of the dough)

- Improved machinability

- Functional added value: in baked goods containing wheat flour, with no additional allergens/e-numbers declaration

- Easy processing

- Optimised nutritional profile

Protein bars and muesli protein bars

For the manufacture of sports snacks where a particularly high protein content is desirable, the use of the plant-based source of protein Lory® Protein H11, with a protein content of over 82.3%, is recommended. In both the classic protein bar with a soft core and for the ‘crunchy’ variant with grains, extruded pops or flakes, this soluble wheat protein can be used in larger quantities.

- High protein content (< 82.3%, N x 6.25)

- Easy, homogeneous incorporation into the base mass

- Processability even at high temperatures (baking)

- Contains valuable amino acids, especially glutamine

(a complete amino acid profile can be achieved by supplementing lysine)

Protein shakes

Due to its high solubility in water and low foam formation, the hydrolysed wheat protein Lory® Protein H11 is optimally suited for use as a plant-based source of protein in beverages and instant drinks. The hydrolysed proteins influence the nutritional profile of the application by adding valuable plant-based amino acids and significantly increasing the protein content, properties that are particularly in demand in the fitness and sports nutrition segment.

- High protein content (< 82.3%, N x 6.25)

- Good dispersibility

- Low increase in viscosity in the application

- Contains valuable amino acids, especially glutamine

(a complete amino acid profile can be achieved by supplementing lysine) - Low foam formation

Injection brine

Along with specialist starches and flours, hydrolysed wheat proteins are a constituent part of Lory® Inject injection brines, which prevent the meat from becoming dry and tough during processing. The functional properties of the hydrolysed wheat proteins not only have a positive effect on the nutritional value of the end-consumer product, they also offer definitive benefits in the productions process: there is no loss of pressure in the injector as a result of foam formation, and the homogeneity of the brine ensures uniform treatment.

- Nutritional optimisation through the addition of plant-based protein

- Neutral taste

- Homogeneous dispersion, low sedimentation

- No clumping

- Low foam behaviour and therefore no pressure loss in the injector

Find out more about our brine additives