Coating systems for numerous applications.

With Loryma’s wheat-based coating systems, your foods become crispier and tastier. In this regard, our batters and dry breading can be used in a variety of ways. They protect the fried or deep-fried food, regulate the product’s moisture and provide the end consumer products with their optimum crispiness and excellent mouth feel. The batters also ensure good adhesion – also in multi-state coating processes. As a producer of wheat-based coating systems with many years of experience, Loryma offers you effective solutions for meat, fish potato products, vegetables and cheese products.

Loryma coating systems for your production and processing:

Sie als Lebensmittelhersteller wollen mehr über die Coatingsysteme von Loryma erfahren? Einen Überblick über unsere Panaden und Coatingsysteme finden Sie in unserer Übersichtstabelle oder in unserem Pressebericht.

Loryma coating systems for crispy, tasty, fail-safe food.

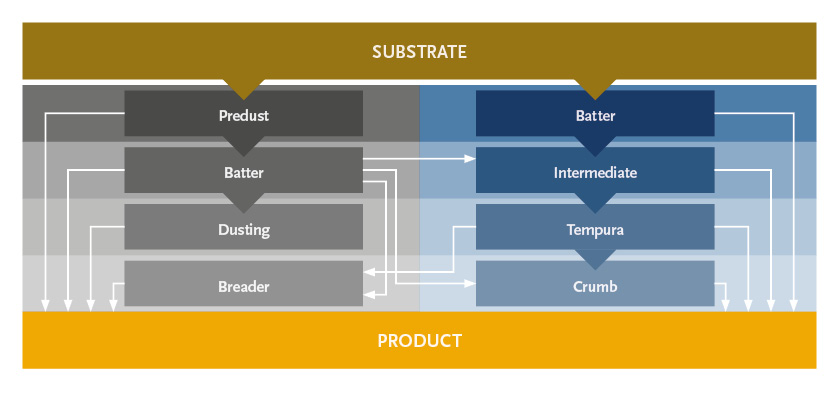

Protect and optimise your products made from meat, fish, potatoes, vegetables or cheese, with Loryma’s coating systems. As a producer of batter and dry breading, we offer you the appropriate system solutions that are precisely adapted to your individual requirements. Our coating systems are tailor-made for the specific requirements of the substrate to be coated. Depending on the product substrate, the intended use and the manufacturing process, you can use the Loryma coating systems to coat in one, two, three and four or more stages.

- Improved crispiness during the deep-frying process, thanks to special Loryma wheat starches

- Freeze/thaw stable

- Very good baking and fermentation stability

- For excellent all-round adhesion

- Optimal protection against increased heat

- Preserves the substrate’s juiciness

- for optimum crispness from crunchy to crispy

- Taste optimisation of the end consumer products

- For an appetising look and excellent mouthfeel

- Available with visuals such as herbs and spices

Pre-treatment, intermediate coating and external coating of:

- poultry

- pork

- fish

- seafood

- potato products

- vegetables

- vegetarian and vegan alternative cheese products

The Loryma coating systems at a glance:

Loryma coating systems for pre-treatment:

Clear Coating: Thin coating | The transparent coatings make the visuals and spices on the product surface visible.

Milkwash: Thin batter | The low-viscosity batter is used for dry surfaces for the preparation of dustings such as, e.g. Camembert for baking

Predust: Predusting | Dusting for optimum adhesion of the following layers.

Glazing: Gel-like coating | Protects the product from moisture loss and prevents icing-up in free-packed frozen products (IQF).

Loryma coating systems as interlayer:

Batter: batter | Depending on the surface condition of the substrate, it ensures optimum all-round adhesion.

Intermediate: intermediate dusting |

Absorbent dry component layer for optimum all-round adhesion, even at the substrate edges

Loryma coating systems as an outer breading:

Tempura: batter | Firm, stable and fluffy to crispy coating with golden-brown, appealing appearance.

Dusting: outer dusting with flour | Protects against drying out and for fixation of moist and unstable substrates

Breader: outer breading | For a crusty, crispy outer crust.

Crumb: bread crumbs | Protection of the substrate during frying and deep-frying with a crisp final result.

Use of Loryma coating systems in single-stage and multi-stage coatings.

Coating stages of the Loryma coating systems at a glance

Depending on the application, the Loryma coating systems can vary in use, from single-stage to multi-stage in various stages and without any problems:

Single-stage coating with Loryma coating systems

When using Loryma coating systems, you can coat your product with single-stage coatings in just one process step, thereby refining its surface, improving its texture and enabling optimum adhesion of visuals and spices. This way, they protect the substrate from drying out and increase product quality. With the individual setting of the pick-up, you optimise your value chain and secure your manufacturing process with perfectly coordinated ingredients. The Loryma coating systems protect the substrate in frying, deep-frying and cooling processes, increase crispness, adhere excellently to moulded products and grown meat, are freeze/thaw stable and enable the fixation of spices and visuals.

Two-stage coating with Loryma coating systems

Two-stage coating with Loryma coating systems consists of a wet and a dry texture-providing coating and is suitable for almost all grown meat pieces and substrates with a firm surface. The Loryma coating systems offer special solutions for smooth, rough, damp and dry surfaces with a uniform layer thickness and individual adjustment of the pick-up. The dry breading can be combined in different ways for a variety of effects.

Three-stage coating with Loryma coating systems

In the three-stage coating process, Loryma coating systems offer both breading and batter composition. Compared to the classic two-stage breading process, the process offers the advantage that optimum adhesion is also ensured with higher pick-ups. Moreover, it is also particularly suitable for substrates with a moist, smooth surface, for instance as is the case with fish and seafood or chicken with skin. With Loryma coating systems, with the three-stage coating, a batter is applied after the predust, to set the pick-up and fix the breading. The final coating with dry topcoat ensures the sensory characterisation of the outer breading. When using the three-stage batter make-up, with Loryma coating system, the coating with milkwash is followed by a coating with the intermediate and the final dough application.

Four- and multi-stage coating with Loryma coating systems

Four-stage and multi-stage coatings with Loryma coating systems are used especially for substrates with a high water content and/or thermal instability, where the breading has to counteract high vapour pressures. They are also used for particularly smooth and dry substrate surfaces, since the milkwash ensures improved adhesion for the actual breading application. The intermediate steps in the coating process can be repeated as required depending on the substrate requirements. The more layers are applied with the Loryma coating systems, the more resistant the breading is to thermally induced pressure differences.