Small-grain wheat starch Lory® Starch Iris: small starch particles – huge effect

Lory® Starch Iris is a functional, hot-swelling wheat starch manufactured by the producer Loryma, with a high share of small starch grains. This results in various process engineering-related advantages such as homogeneous distribution of the particles in dispersions and very good gelation for a variety of food applications. Here, in particular, our small-grain wheat starch is extremely well-suited as a rice starch substitute or as a replacement for titanium dioxide.

Optimise your food products with small-grain wheat starch made by the food ingredients producer, Loryma

The Lory® Starch Iris small-grain wheat starch, made by the food ingredients producer, Loryma, offers you new possibilities when it comes to the production and optimisation of your food products. What is more, Lory® Starch Iris provides the basis for new food concepts and sustainable food innovations with natural ingredients that are completely without E numbers.

- Very small starch granules (< 10 µm)

- For the same quantity, ten times more particles than conventional corn or wheat starch, one hundred times more than potato starch

- Very large particle surface

- White, tasteless and odourless powder

- No E numbers

- Substitute for costly rice starches

- Free-flowing and dispersible

- Homogeneous distribution in the food

- Slow sedimentation

- Good digestibility

- High water absorption

- Pronounced gelation after gelatinisation

- Ensures a firm texture

- Adds body to the flavour

- Label-friendly

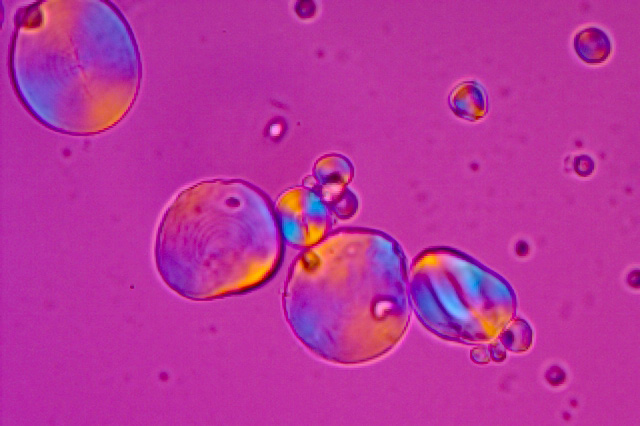

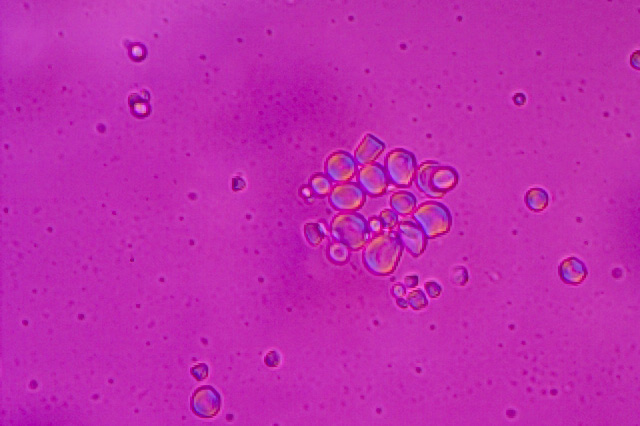

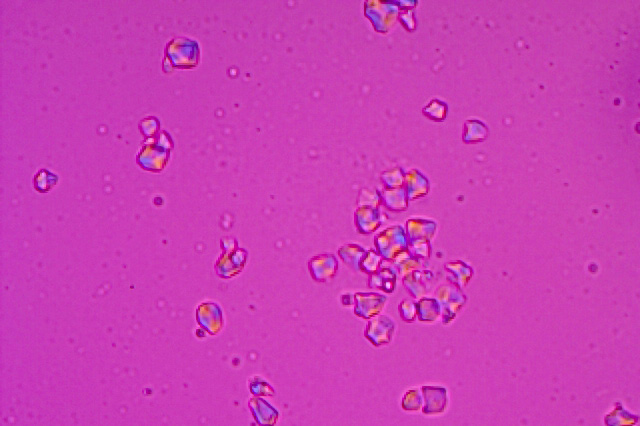

A comparison of the starch particles

The Lory® Iris small-grain wheat starch is characterised by extremely small starch grains (< 10 µm) and, as such, a large particle surface. This makes it a cheaper alternative to rice starch and even provides a substitute for titanium dioxide in food. The following pictures demonstrate the differences of the starch particles in particle size and shape of normal wheat starch, Lory® Starch Iris small-grain wheat starch and rice starch (magnification 400x).

Wheat starch

Wheat starch

Small-grain wheat starch Lory® Starch Iris

Small-grain wheat starch Lory® Starch Iris

Rice starch

Rice starch

Application possibilities

Injections and tumbler brines

In meat products, Lory® Starch Iris promotes juiciness. The large number of small starch grains penetrate the animal tissue evenly and bind released water. The brine only sediments slowly, thereby improving process reliability during production interruptions.

- The treated meat’s texture does not become watery

- Juiciness is increased

- Slow sedimentation, thus increasing process reliability in case of production interruptions / product changes

- Processing in tumblers:

- Small starch particles have a better tissue penetration than ordinary cereal or root starches

- No streak formation

- Processing per injection:

- No solid sediments, no clumping

- Optimal needle mobility

Cooked and scalded sausages

Lory® Starch Iris binds the water released in the sausage mass during cooking and scalding processes, in addition to preventing “water pockets” formation. This is achieved, thanks to the even distribution of the small starch grains. The strong gelation reduces cooking loss as a result of heating and ensures a stable texture with excellent cuttability and firm bite.

- Binds released water

- Equal distribution of the starch prevents water nests

- Less weight loss when heating

- Strong, uniform gelation

- Excellent cuttability, stable texture and firm bite

Dragées, confectionery and snacks

The Lory® Starch Iris small-grain wheat starch can be used as a white pigment when coating medical tablets or in coatings for foods such as nuts, crispies, chocolate or other chunky goods. Unlike colour additives such as titanium dioxide (E171), Lory® Starch Iris poses no health risk. It is natural, unmodified and does not have an E number. Uniform narrow particle size distribution creates an even surface.

- Natural, white colour pigment, with a high degree of whiteness

- High fineness

- Even distribution

- Even surface

- Replaces titanium dioxide and rice starch

- No E number

- High dry substance in the pan-coating solution

- Ideal for white coatings (e.g. dragées)

| L* | a* | b* | |

|---|---|---|---|

| Lory® Starch Iris | 98.17 | -0,10 | 2.34 |

| Rice starch | 98.81 | -0.18 | 2.21 |

- L* indicates the brightness (“whiteness”) Scale: 0 black, 100 white

- a*: +red/-green components

- b*: +yellow/-blue components

Convenience products

Dry soups, sauces and other powder mixtures are examples of applications that are optimised by the Lory® Starch Iris small-grain wheat starch, which serves as a carrier and release agent. Thanks to its small particles, wheat starch offers a large surface area on which other substances such as fats or flavours stick.

- Carrier substance, with large particle surface

- High loading possible, for instance with fats and flavour oils

- Replacement of rice starch, improved cost effectiveness

Baked goods

Lory® Starch Iris can also serve as a release agent, for example in icing sugar, or directly, for dusting dough pieces. The large number of particles reduces the contact of ingredients in reactive mixtures such as baking powder, which increases shelf life.

- Release and separating agent

- Improves free-flowing ability

- Delays the component reaction, increasing shelf life

- No lumping

- Reduces sticking together of doughs and semi-baked goods

- Replacement of rice starch, higher cost effectiveness

Breadings and Clear Coatings

In breadings, Lory® Starch Iris promotes the product’s crispiness and ensures better adhesion. The small-starch grains can penetrate the substrate’s surface and bind water exactly where it is formed during cooking. With a wafer-thin starch-based clear coating, French fries and other fried vegetables remain crispy for longer and absorb less fat.

- Breadings with crunch effect

- Improved adhesion on substrate

- Supports surface film formation

- Substrate protection

- Clear coating protects visible herbs and spices

- Replacement of rice starch, improved cost effectiveness