Plastic flood? Alternatives made from domestic raw materials are available!

How corrugated board with a high performance wheat starch adhesive ensures more sustainability

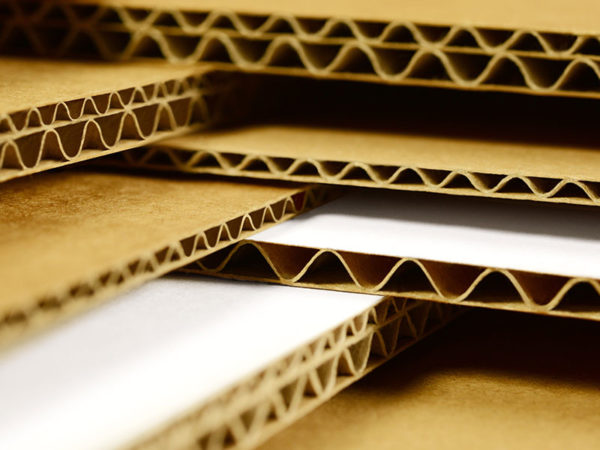

Avoiding plastic in all areas of our lives plays an important role in protecting our earth and its resources. Especially when it comes to packaging, in online trade and when exporting goods, large amounts of plastic waste can be saved with sustainable paper, cardboard and paperboard packaging solutions. Corrugated board plays a decisive role in this regard. Being light and stable, corrugated board is used almost everywhere where goods need to be protected and transported.

It is produced by gluing smooth and corrugated paper webs together, which leads to a stable firmness. For this purpose, the corrugated board industry needs special adhesives that satisfy high standards of environmental friendliness, recyclability and efficiency.

Paper, cardboard and paperboard have a CO2 footprint that is about five times smaller than that of plastic.

Paper, cardboard, paperboard: 676 kg CO2/t compared to plastic: 3,453 kg CO2/t.

Starch-based, high-performance wheat adhesives for high-quality corrugated board

Corrugated board is a natural product that consists predominantly of domestically-sourced, renewable raw materials. It is 100 per cent recyclable and can be recycled up to 20 times. The use of starch-based, high-performance adhesives is what makes recycling possible in the first place. If synthetic adhesives were to be used instead, then paper and corrugated board would no longer be recyclable. This, in turn, would have serious consequences regarding ecological aspects, as well as the decomposition of valuable materials and the CO2 balance.

C&D Corrugating & Paper high performance adhesives, made from wheat starch, bond the paper layers quickly, securely and firmly. Thanks to their optimum composition, less adhesive is used during gluing, while still fully exploiting the performance of the corrugated plant. The starch-based, high-performance adhesives optimise energy use, in addition to creating less waste.

Corrugated board is one of the most widely-used packaging materials. On average, corrugated base paper consists of 79 per cent secondary and 21 per cent primary fibres. Thus, used and recycled corrugated board packaging is also the most important raw material for producing raw paper. The necessary primary fibre content is obtained from broken and thinning wood.

Wheat – a sustainable raw material for sustainable applications

The natural raw material of wheat offers numerous possibilities for multifunctional industrial use and opens up a range of environmentally-friendly solutions with added value. It is sustainable throughout the value-chain: from sowing, right up to processing. While growing, wheat binds large amounts of CO2. In addition to low transport emissions, it is also really versatile. By means of joint-product production, i.e. the manufacturing of various products from a single starting material, the wheat can be recycled almost completely, with a yield of 99 per cent. This guarantees efficient and resource-saving handling. At Crespel & Deiters, only German or European GMO-free wheat is processed. Starches and plant proteins are obtained from the regional, renewable raw material. While wheat proteins are widely used in the food and feed industry, wheat starch is used to produce customised adhesive concepts for the corrugated board industry.

Starch in corrugated board production

Whereas 494,000 tonnes of starch were used in paper production in 2012, the figure rose to 580,000 tonnes by 2017. This represents an increase of nearly 20 per cent.

With a growth rate of almost 30 per cent (28.9 per cent) over the same period, the use of starch in the production of corrugated board has increased even more significantly.

• 2012: 91,500 tons

• 2017: 118,000 tons

5.4 million tons of corrugated board were produced in 2018. This represents an increase of 2.5 per cent over the previous year. Production has even increased by 15.8 per cent since 2013.

More sustainability, with sustainable solutions made from wheat

In particular, the economy has the task of using its expertise and innovative capacity to offer new solutions that are flexible in satisfying consumer needs and also respect nature and the environment. Wheat offers an array of convincing arguments for this. It is natural and regional, but also absolutely multifunctional. As a renewable raw material with a long tradition, it combines high sustainability with economic added value, in addition to enormous innovative power and efficient application.